Overview of sawdust dryer

With the fast growth of industrialization and the rapid consumption of resources, emerging biomass energy has attracted the attention of the country and industry. Various kinds of wood chip, sawdust, crop straw and edible mushroom residue have been changed from discarded waste into available resource and are used to produce wood chips and biofuels with high combustion value, and all wood chips and crushing waste shall be dried and processed.

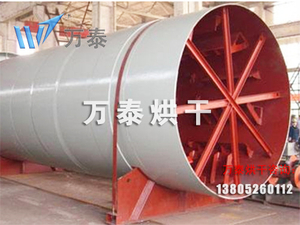

WAN TAI sawdust dryer is widely applied to the industries such as straw briquette, charcoal machinery, wood pellet fuel, sawdust briquette and husbandry engineering.

Characteristics of sawdust dryer

1. Large drying strength; due to high dispersion of materials in the air, all surfaces of particles are the effective area of drying.

2. Short drying time, controllable drying moisture.

3. Simple structure, small floor area, easy to build and repair.

4. Large processing capacity, high thermal efficiency. When drying unbound water, the thermal efficiency can reach 60%.

Principle of sawdust dryer

The sawdust dryer includes heating furnace, feed port, rotating cylinder, filter cylinder, material conveying pipe, cooling cylinder and discharge port. The rotating cylinder is arranged on the active roller which rotates at a low speed by means of the rotation of rotating cylinder driven by the motor and gearing-down belt; there is a feed port between the heating furnace and rotating cylinder. The shoveling vanes are arranged in the rotating cylinder. A baffle is provided with a small hole and installed at the connection between the rotating cylinder and filter cylinder; one end of the filter cylinder is connected with the rotating cylinder, and the other end is connected with the material conveying pipe. The filter cylinder is provided with a stopper inside and slag discharging holes in the bottom. One end of the cooling cylinder is connected with the material conveying pipe through a blower, and the other end is connected with the discharge port.

Due to the above structure, the sawdust can be fully dried in the rotating cylinder. Sawdust is fully dispersed before entering the material conveying pipe, so the moisture can be evaporated quickly; the stopper can block sundries of sawdust so as to ensure the quality of sawdust entering the material conveying pipe. After entering the sawdust dryer, sawdust will boil and be fluidized in the cylinder under the action of spraying pipe and rotating cylinder, and the hot air will be fully contacted with the material for drying.