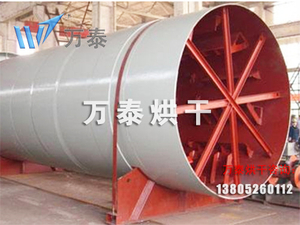

Working principle of wood chip dryer

The wood chips enter the internal cylinder from one end, go back to the middle cylinder under the action of shoveling plate, bend toward the external cylinder again and discharged from the other end after drying, which is equivalent to three times of the length of the rotating cylinder and greatly reduces the equipment volume. It has the advantages such as high thermal efficiency, light weight, wide adaptability and flexible temperature control.

Characteristics of WAN TAI wood chip dryer

1). The thermal efficiency of self-insulation three-cylinder system is more than 75% (the thermal efficiency of the traditional single-cylinder dryer is only 35%), which improves the thermal efficiency by more than 50%;

2). The land occupation of single-cylinder dryer is reduced by about 45%, the civil construction investment by about 40% and the power consumption by 55%.

3). The final water content and material flow can be controlled according to the user's requirement;

The wood chip dryer produced by Wantai machinery adopts three drum rotary drum structure, with advantages of

1. The investment required for the equipment is 1 / 6 of the imported products;

2. The thermal efficiency rate of the cylinder self insulation is over 70% (the thermal efficiency of the traditional single cylinder dryer is only 35%), and the thermal efficiency is increased by more than 50%;

3. Adopt the tail drive, the drive is more stable and reliable, completely change the phenomenon that the roller drive often slips and affects the production;

4. Compared with the single barrel dryer, the floor area is reduced by about 50%, the civil construction investment is reduced by about 50%, and the power consumption is reduced by 60%;

5. The combination and distribution of various weekly lifting materials can effectively control the drying time, and the drying effect is good;

6. It can easily adjust and control the required final moisture index according to the user's requirements;

7. Adopt frequency control to control material flow;

8. The gas outlet temperature is low, the dust removal equipment has a long service life, and the next process can be carried out continuously;

9. It is equipped with a new type of energy-saving hot blast stove, which is efficient, energy-saving, controllable in thermal engineering, simple in operation and with a reduction of coal consumption of about 60%;